HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

product category

Add:North Side, Haomen Road, Yutian County, Tangshan City, Hebei Province, China

Sale Mobile:13931543095

Tel:0315-6117767

01. The most prominent feature of this machine is that it is fully computer controlled, so that it is easy to use, highly intelligent, stable in quality and fast. It both enhances economic performance but significantly saves labor.

02. As a stitching and folder gluer machine, it can glue cartons, stitch cartons, and also first glue and then stitch cartons.

03. There is the order memory and storage function so that new order setting can be finished within 3 to 5 min and then mass production can be launched. It realizes one-key switch between stitching and gluing in the real sense. The fault diagnosis function automatically stops the machine in the case of any fault and displays on the touch screen the fault cause and location, so that the fault can be quickly eliminated and waste can be greatly reduced.

04. It is suitable for stitching three wall, five wall and single wall boards, as well as A, B, C and AB corrugated sheets.

05. The feeder uses a vacuum feeding mechanism to ensure accurate feeding without going oblique. There is a side flapping device to neatly align the paper during feeding.

06. It can also stitch cartons without a bottom but with a cover.

07. Range of stitch spacing: 40 mm (min.) - 90 mm (max.).

08. Max. stitching speed: 1200/min.

09. There are two speed modes available: high speed mode and accurate mode. Suppose each carton needs three stitches and has a height of 400 mm; then, the highest speed is 9000 pcs/h.

10. It can automatically fulfill paper feeding, folding, deviation correction, stitching, gluing, counting, stacking and output.

11. You can freely switch between single staple and double staples.

12. A running stitching head is used, featuring low power consumption, higher speed, higher stability and effectively enhanced stitching quality.

13. A paper alignment & correction device is used for secondary compensation and correction of incorrectly positioned board, thereby eliminating scissors openings and improving the stitching performance.

14. The automatic wire feeder can realize wire detection, including broken wires and wire shortage.

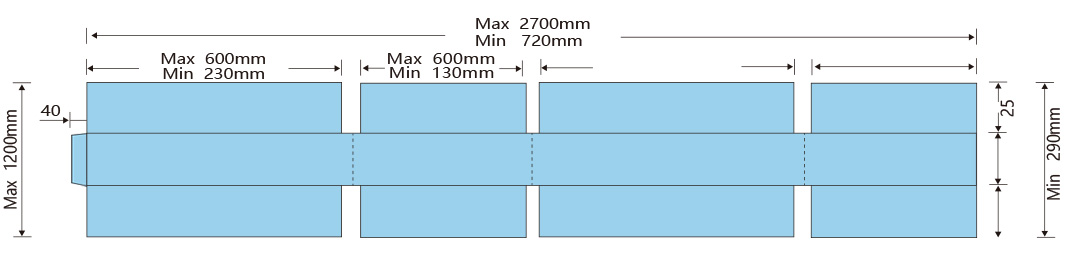

| Max. Paper Width | 1200×2700mm |

| Min. Paper Width | 300×800mm |

Feed rate | 0-130m/min |

| Power Required | 30KW |

| Overall total current rating | 70A |

| Power supply | 3-phase 4-wire supply(3-phase 380 V + neutral) |

| Overall Dimension | 15945×3644×1950mm |

| Machine Weight | 12.5T |

01

01

1.The main motor with an inverter contributes to silent running of the system and flexible and stable speed control.

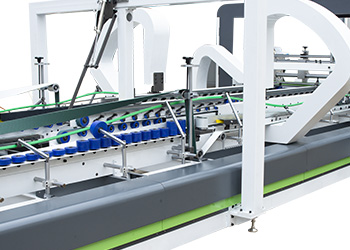

2. Vacuum belt is used for feeding the paper and 8 blowers whose air volume is freely adjustable realize accurate and reliable paper feeding.

3. The high-end electromagnetic clutch brake system makes it possible to separately control the feeder, and it is easy to operate.

4. The front baffle and feeding belt of the feeder are sidewise adjustable and the front feeder can be electrically adjusted so that the feeding needs of various sizes of cartons can be easily satisfied.

5.The gap is adjusted with eccentric wheel to accommodate paperboards of different thicknesses.The suitable paperboard thickness is 3 to 8 mm.

6. Knurl wheel bottom gluing is adopted and the glue applicator can adjust the gluing width to ensure uniform glue application, zero omission and less glue consumption. The gluing speed is synchronized with that of the main machine, thus reducing the friction between the glue roller and the paperboard and extending the life of the glue roller.

02

02

1.It is linked with the feeder and equipped with an inverter.

2. Imported high-friction belt and timing belt are used to feed paperboard which is automatically folded, effectively preventing non-uniform paperboard thickness or different tension of both belts from causing scissors openings.

3. The folder is equipped with a paperboard correction device, an indentation correction device and a flapping correction device to effectively compensate and correct the improper folding in the slotting process and to avoid scissors openings.

4.Folding speed: 130 m/min.

03

03

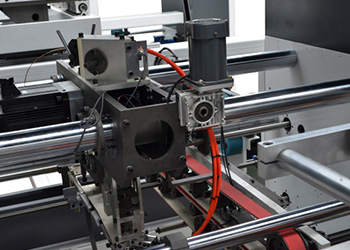

Servo motor and timing belt are combined to drive three flaps, thus constituting a flapping paper alignment &correction device which can minimize paperboard damages, make secondary compensation and correction of incorrectly positioned board and eliminate scissors openings, thus improving carton stitching performance. The main motor is a VECTOR servo motor. The belts for paper feeding are of domestic famous brand. The servo motor drives the flaps through the timing belt to realize alignment of cartons and facilitate accurate control of the flaps.

04

04

05

05

1.When gluing is finished, the cartons are flapped again, counted, stacked and automatically discharged by the dozen.

2. There is differential correction and the stacking speed is 130 m/min.

3. Counting and ejection are realized in a pneumatic way, featuring reliable, accurate and rapid movement.

4. There is an emergency stop switch to avoid waste of paperboard in the case of an emergency.

06

06

1. A touch screen is used to enter various carton data, and to realize size adjustment and change of order. It is easy to use and works reliably.

2. It features data input without stopping the machine, automatic counting and accurate output.

3.30KW Total installed capacity: 30 kW.

The electric control system uses the latest Mitsubishi PLC computer automatic control system for thorough inspection and control ranging from paper feeding, folding, arrangement, stitching to delivery. Japan Fuji contactor is also used.

The HMI display system can display various working conditions, locate the fault position and give the solution. There is a variety of safety devices which will give a sound-light alarm and automatically stop the machine in the case of a fault, thus ensuring the safety of both people and the machine.

公安备案号:13022902000193

公安备案号:13022902000193

Sale Mobile

Tel

Applets