HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

product category

Add:North Side, Haomen Road, Yutian County, Tangshan City, Hebei Province, China

Sale Mobile:13931543095

Tel:0315-6117767

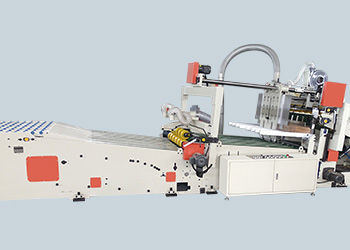

1、The biggest advantage of this machine is computer operation which is simple to use, stable quality, high speed and greatly saved labor.

2、The machine can stitch or glue three-layer and five-layer corrugated board. It also applied on corrugated carton box without a cover.

3、The machine contains a function of order memory and order storage.it can help us transform another order and produce in a few minutes.Using a computer screen to display operation and fault description,for this reason we can solve the fault expediently and improve work efficiency .

4、The feeder section feeds paper by the lead edge feeding method, and it can protect the paper from skew. The belt can be adjusted individually in order to extend work life.

5、The stitch head and plastic are controlled by servo motor.The stitch distance and pin number are accurate and stable.

6、The stitch head adds adjustment function,finished products don’t have scissors fork or bevel edge.

7、Maximum stitching speed: 1100 nails/minutes.

8、Single nail and double nails can be adjusted freely,the maximum range achieves 90mm.The intensive nail range can achieve 70mm.

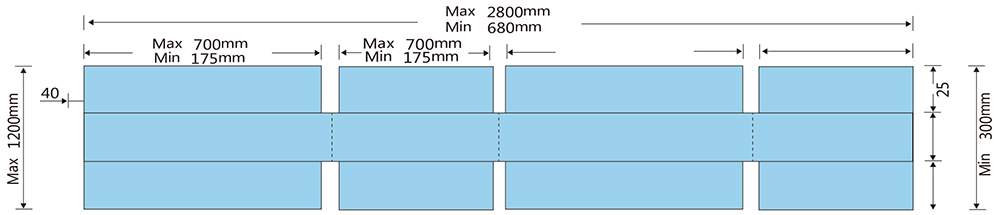

| Model | AFS-2800B |

| Max. Paper Width | 1200mm |

| Min. Paper Width | 300mm |

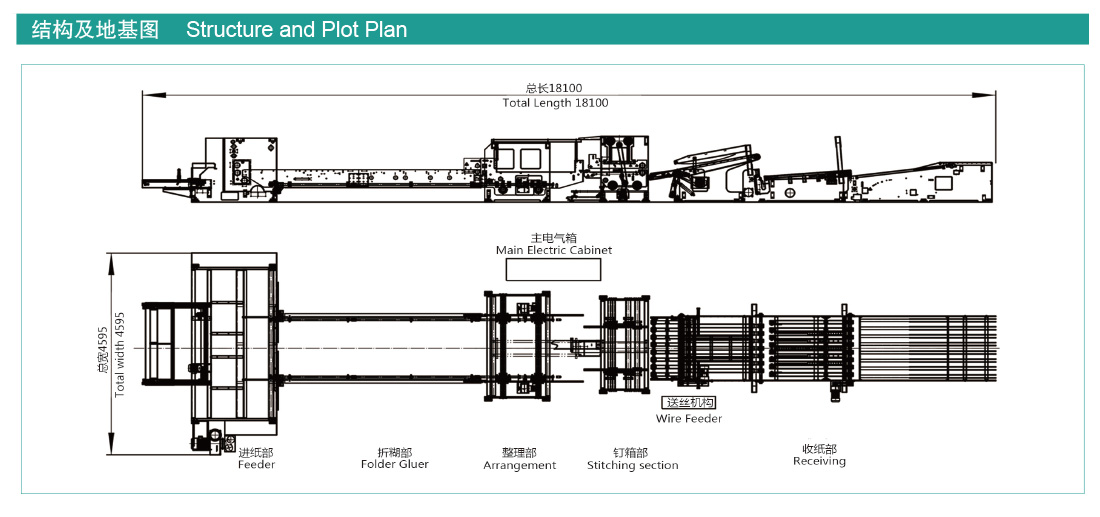

| Machine Width | 4595 |

| Machine Length |

Stitching 15.5m Stitching/Folder Gluer 18.1m |

| Max. Paper Length | 2800mm |

| Min. Paper Length | 850mm |

| Max. TS Width | 40mm |

| Power Required | 28.5Kw |

| Installation Area | 18100×4595mm |

| Stitching Speed(Nails/Min) | 1100 |

| Machine Weight | 22T |

| Pitch of Nails for Single Nail and Double Nails (Min.-Max.) | 30-90mm |

| Pitch of Nails for Intensive Nail(Min.-Max.) | 30-70mm |

| Paste Speed | 130米/分 |

| Air Pressure | 0.6-0.8Mpa |

01

01

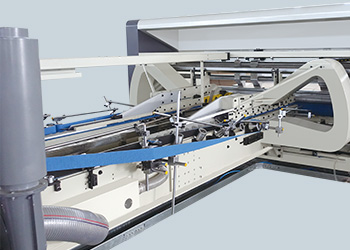

The feeding part adopts the leading edge feeding structure. The air cylinder uses Taiwan Mindman air cylinder. Other accessories are all imported with high quality, such as Taiwan Mindman Fish-eye coupler, Japan Mitsubishi Inverter, Japan Panasonic photoelectric switch.

02

02

The folding part is made of Japan NITA perforated belt, which is vacuum absorbed throughout the whole process. In order to achieve perfect cardboard indentation, a new set of pre-pressing is added to the front end of folding part. The suspension system is adopted in the inclined pressing wheel, and the paper feeding is stable without slipping can be ensured in the second pre-folding. Meanwhile, the wall panel is processed in one time by the computerized numerical control so that the dimensional accuracy can be achieved. The differential of the upper and lower belts can be adjusted automatically to ensure folding and alignment.

03

03

The paper-correcting device is used in arrangement part in order to perform secondary compensation and correction of the box not in place, eliminating the scissors opening and making the nail box more perfected.

04

04

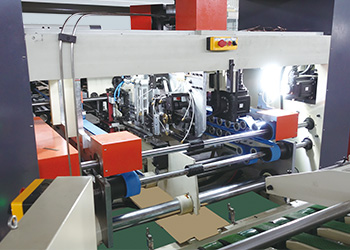

The stitching section is equipped with two Mitsubishi high-power servo motors, Mitsubishi's latest programmable logic controller (the PLC computer system) and WEINVIEW touch screen control system which ensure the accurate operation of electrical appliances. Running nail head uses Italian parts, which can ensure the mechanical operation is stable and durable. Centralized lubrication system can significantly reduce the wear of lubricating parts, so that the wear of the lubricating parts can be reduced, which can effectively extend the life of the nail head components by 60-80% and improve the maintenance efficiency. The speed of the running nail head is faster and the appearance is more beautiful, which can effectively improve the quality of the finished nailing box. The advantage of the machine head is that there are few adjustable places, and the size of each part is mainly ensured by the precision of the parts.

05

05

The device of drop-type paper receiving is adopted to reduce scratches, which is equipped with automatic tapping device, the function of automatic counting. Meanwhile, the number of paper piles can be set freely, which is more convenient.

公安备案号:13022902000193

公安备案号:13022902000193

Sale Mobile

Tel

Applets